For construction, mining, and earthmoving professionals, a dozer’s cutting edge is make-or-break for productivity. A worn edge doesn’t only slow operations, but also drains profits through wasted fuel, frequent replacements, and hours of avoidable downtime.

Choosing the right dozer cutting edge supplier doesn’t mean a casual purchase, it’s a strategic move to protect your project’s timeline and bottom line. This guide reveals how to spot durable, OEM-compatible edges and partner with a supplier that delivers global reliability.

1. The Hidden Costs of a Worn Dozer Cutting Edge: Why “Cheap” Parts Cost More

A worn cutting edge isn’t only a maintenance issue, its also impact ripples through your entire operation:

Plummeting Efficiency: A dull edge loses its original sharpness, increasing slip by up to 20%. The fuel consumption of your bulldozer will increase by 15% per hour by taking longer time to move dirt and rock while the efficiency of earth moving will decrease.

Cascading Equipment Damage: When an edge wears excessively, it exposes the dozer’s moldboard. The cost of replacing a moldboard is five times than replacing cutting edge in advance

Unplanned Downtime: Changing a cutting edge takes 2–3 hours per side. If you replace edges monthly, there will be more than 24 hours of the downtime each year, which the team could spend on generate revenue.

2. Key Factors of a Durable Dozer Cutting Edge: What to Look For

Not all cutting edges are created equal. Durability comes from engineered precision:

a. Premium Materials & Heat Treatment

The best dozer cutting edges use:

High-performance steels: Choose between high-carbon boron steel or alloy steels. These alloys balance:

Hardness: 450–500 HB (Brinell scale) to resist abrasion.

Toughness: To absorb impacts (e.g., rocky terrain) without cracking.

Precision heat treatment: Computer-controlled quenching/tempering ensures uniform hardness—so edges wear slowly without becoming brittle.

Avoid: Cheap, low-carbon steel edges—they deform or snap short time.

b. OEM Compatibility & Exact Fit

A “close enough” fit leads to uneven wear and stress breakage

Pay attention to below points:

1:1 OEM replication: Edges engineered for your dozer model

Precision engineering: 3D-scanned bolt holes and contouring ensure seamless installation—no grinding or modifying required.

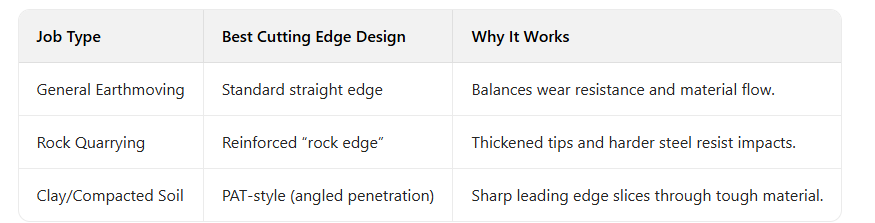

c. Application-Specific Design

Match the edge to your work:

3. Essential Traits of a Dozer Cutting Edge Supplier (For Global B2B Buyers)

Your supplier should be a partner in uptime, especially for international buyers:

a. Strict Quality Control & Certifications

Proof of quality:

ISO 9001 certification: Ensures a standardized, reliable manufacturing process.

Batch testing: Look for suppliers who test edges for hardness (Rockwell/Brinell), impact resistance (Charpy test), and dimensional accuracy.

b. Technical Expertise (Not Just “Selling Parts”)

A great supplier advises you:

“Which edge is the best for abrasive sand vs. hard granite?”

“How do heat treatment differences impact lifespan?”

c. Wide Range + Customization

Pay attention to below points:

Full catalog coverage: Edges for all major dozer brands/sizes (Caterpillar, Komatsu, Liebherr, Volvo, etc.).

Custom solutions: Need a 12-foot edge for a specialized dozer? Or a super-hard alloy for Arctic conditions? A top supplier delivers—fast (30 days lead times for custom orders).

d. Global Export Proficiency

For international buyers, seamless logistics are critical:

Export-ready packaging: Plastic bag + wooden crates (protects edges during long ocean freight).

Documentation expertise: Accurate Bill of Lading, Certificate of Origin, Commercial Invoice, no customs delays.

Regional experience: We’ve shipped to 60+ countries (EU, USA, Australia, Middle East) and know local import regulations.

Why NINGBO HUIFENG MACHINERY SPARE PARTS CO., LTD Is the Global Choice for Dozer Cutting Edges.

At NINGBO HUIFENG MACHINERY SPARE PARTS CO., LTD, we’ve spent over10 years as a trusted B2B partner for heavy equipment fleets worldwide. Here’s how we deliver value:

OEM-Quality: Our edges use NM500 boron steel and precision heat treatment. Tests have shown that OEM hardness standards (500+ HB) while retaining impact toughness.

Perfect Fit for Major Brands: 3D-scanned to match Caterpillar, Komatsu, and 50+ other OEM specs, bolt on and work immediately.

Proven in Tough Conditions: Mines in South Africa, quarries in Germany, and construction firms in Brazil trust our edges to outlast competitors.

Seamless B2B Export: We handle all logistics from packaging to shipping. Clients in Dubai, Rotterdam, and Houston get orders from our factory to their site.

Take Action: Maximize Your Dozer’s Uptime Today

Stop letting worn edges drain your profits. Partner with a supplier that prioritizes your productivity.

✅ Get a FREE Custom Quote in 24 Hours

(Select your dozer model, application, and quantity, we’ll send a detailed quote + technical specs.)

✅Download Our Dozer Cutting Edge Catalog (PDF)

(Explore 200+ models, OEM compatibility charts, and wear-resistance data, free for B2B buyers.)

✅ Call Our Multilingual Team Now

+86-13957476951 |info@tigerget.com

Contact: WANGWEI

Phone: 0086-13957476951

E-mail: info@tigerget.com

Add: Room No.401-36,TianJian Lane No.26,Yinzhou District,Ningbo City.